SHUANGLONG GROUP CO., LTD.

Business units

ChinaVIP0Audited Supplier

Products: Batch/Continuous Mixer , Powder/Liquid/Paste Mixer , Conical Mixer , Plough Mixer , Paddle Mixer.

Response Time: within 24 hours

Response Rate: 100%

+ Follow

View Shop

Chat Now

Add to wish list

+ Add a New List

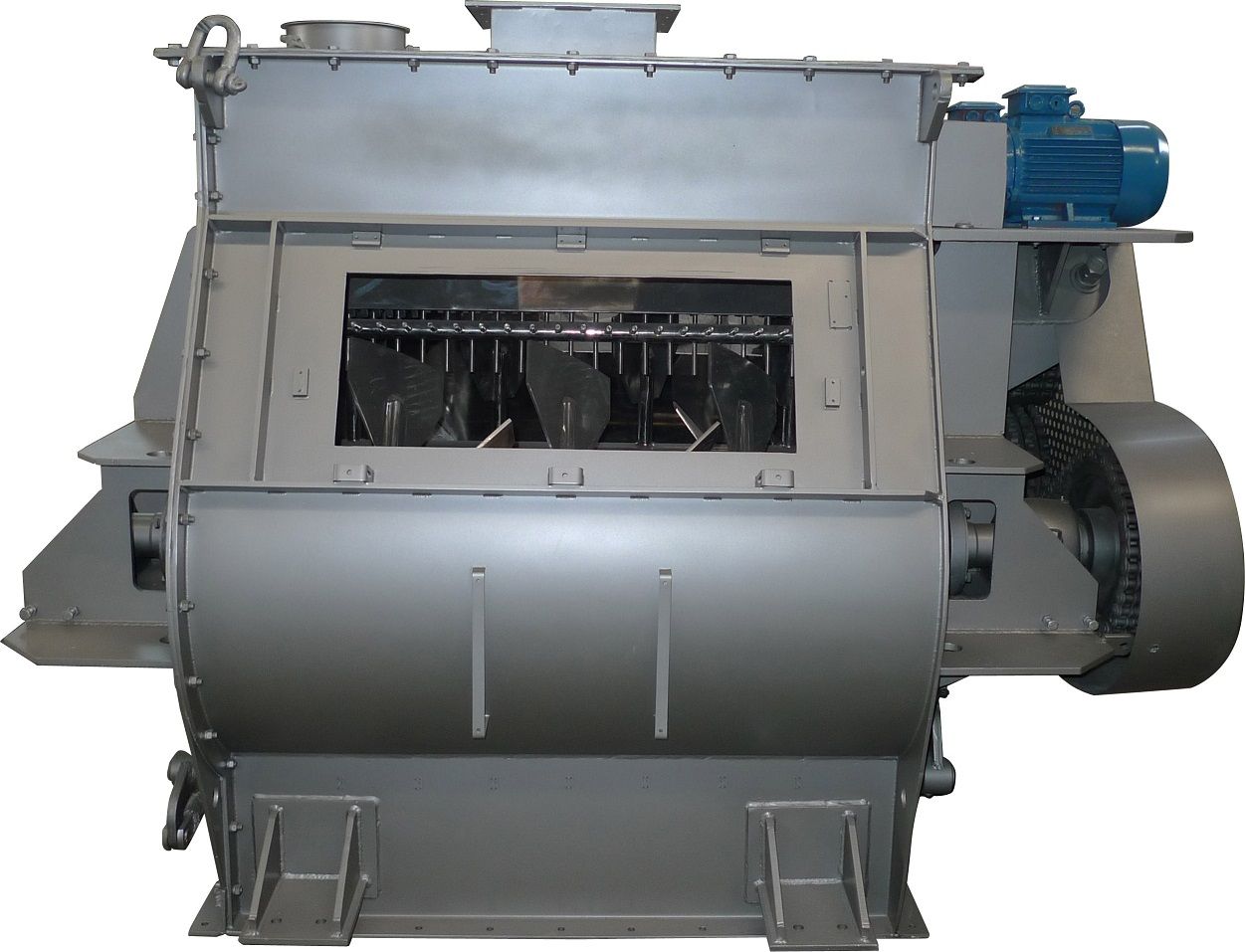

Dry Mortar Paddle Mixer

$5000.00 /piece

Product Details

Transaction Comments

Basic Info

- Model NO.: WZ

- Mixer Type: Powder Mixer

- Stirring Type: Gravity

- Application Area: Agricultural Chemicals

- Additional Capabilities: Drying

- Trademark: Shuanglong

- Origin: Shanghai, China

- Certification: CE, ISO

- Working: Convection Mixer

- Application: Liquid with Suspended Solids, Powder, Granules

- Layout Type: Horizontal

- Operating type: Cycle Operating

- Specification: CE, ISO9001

- HS Code: 84798200

Product Description

Introduction:

Double Shafts Paddle Mixer is a new type of high homogeneity mixer which makes material weightless during mixing. It is widely used in heavy bulk density, high viscosity material such as dry mortar, metal, rubber, mining, plastic, chemical, Metallurgy industry and to meet highest homogeneity.

Working Principle:

The two axes of mixing interior rotates to different sides and paddles attached to the axes forms fluidized area by diffusing mixed materials to different directions according to stable apex speed. At this time, the movement of materials is concentrated on the higher center part from the bottom of mixer, and therefore, the effective volume of mixing room increases, and as the effective volume increases, the collision and rubbing between materials decrease. Also, as the contacting section between materials and the mixing room, there is no damage because of collision and rubbing, and on the other hand, mixer itself does not cause inner rubbing because of material, so it keeps the shape of particle, and as it does not press rotating object or vent-less etc., it prevents the leakage of materials on the seal part and proceed mixing. Like this, zero-gravity mixer became created the new concept of powder mixing by solving problems of eruption and leakage etc, as well as precision of mixing.

Features:

· Volume: 100-18000L

· Stainless Steel or Carbon Steel

· Ribbon agitator for center discharge

· Designed for normal temperature and normal atmospheric pressure

· Feed Nozzle

Dust Nozzle

· Manually operated or Pneumatic operated flap valve

· Packing Seal

Safety limit switch on man hole

Datasheet:

Applications:

Double Shafts Paddle Mixer is a new type of high homogeneity mixer which makes material weightless during mixing. It is widely used in heavy bulk density, high viscosity material such as dry mortar, metal, rubber, mining, plastic, chemical, Metallurgy industry and to meet highest homogeneity.

Working Principle:

The two axes of mixing interior rotates to different sides and paddles attached to the axes forms fluidized area by diffusing mixed materials to different directions according to stable apex speed. At this time, the movement of materials is concentrated on the higher center part from the bottom of mixer, and therefore, the effective volume of mixing room increases, and as the effective volume increases, the collision and rubbing between materials decrease. Also, as the contacting section between materials and the mixing room, there is no damage because of collision and rubbing, and on the other hand, mixer itself does not cause inner rubbing because of material, so it keeps the shape of particle, and as it does not press rotating object or vent-less etc., it prevents the leakage of materials on the seal part and proceed mixing. Like this, zero-gravity mixer became created the new concept of powder mixing by solving problems of eruption and leakage etc, as well as precision of mixing.

Features:

· Volume: 100-18000L

· Stainless Steel or Carbon Steel

· Ribbon agitator for center discharge

· Designed for normal temperature and normal atmospheric pressure

· Feed Nozzle

Dust Nozzle

· Manually operated or Pneumatic operated flap valve

· Packing Seal

Safety limit switch on man hole

Datasheet:

| Model Project | All volume (M3) |

Loads coefficient | Electrical machiney power (KW) |

Size(mm)× Max-diameter ×High | Equipment weight (kg) |

| WZ-0.05 | 0.05 | 0.4-0.6 | 1.5 | 1290×660×837 | 230 |

| WZ-0.2 | 0.2 | 0.4-0.6 | 4 | 1124×1110×720 | 260 |

| WZ-0.4 | 0.4 | 0.4-0.6 | 4 | 1400×1250×1030 | 450 |

| WZ-0.5 | 0.5 | 0.4-0.6 | 7.5 | 1450×1500×950 | 800 |

| WZ-1 | 1 | 0.4-0.6 | 11 | 1800×1800×1350 | 1150 |

| WZ-1.5 | 1.5 | 0.4-0.6 | 15 | 1850×1950×1180 | 1500 |

| WZ-2 | 2 | 0.4-0.6 | 18.5 | 2200×2400×1600 | 2800 |

| WZ-2.5 | 2.5 | 0.4-0.6 | 18.5 | 2300×2300×1620 | 4200 |

| WZ-4 | 4 | 0.4-0.6 | 22 | 2680×2400×1850 | 4500 |

| WZ-5 | 5 | 0.4-0.6 | 37 | 2950×3050×2040 | 6000 |

| WZ-6 | 6 | 0.4-0.6 | 45 | 3050×3250×2100 | 7000 |

| WZ-10 | 10 | 0.4-0.6 | 55 | 3550×3150×2400 | 8000 |

| WZ-13 | 13 | 0.4-0.6 | 55 | 4695×3180×2500 | 10500 |

| WZ-15 | 15 | 0.4-0.6 | 55 | 4180×3960×2600 | 10000 |

| WZ-18 | 18 | 0.4-0.6 | 75 | 5700×3700×2500 | 13000 |

Applications:

Other products from this supplier

Back to top