SHUANGLONG GROUP CO., LTD.

Business units

ChinaVIP0Audited Supplier

Products: Batch/Continuous Mixer , Powder/Liquid/Paste Mixer , Conical Mixer , Plough Mixer , Paddle Mixer.

Response Time: within 24 hours

Response Rate: 100%

+ Follow

View Shop

Chat Now

Add to wish list

+ Add a New List

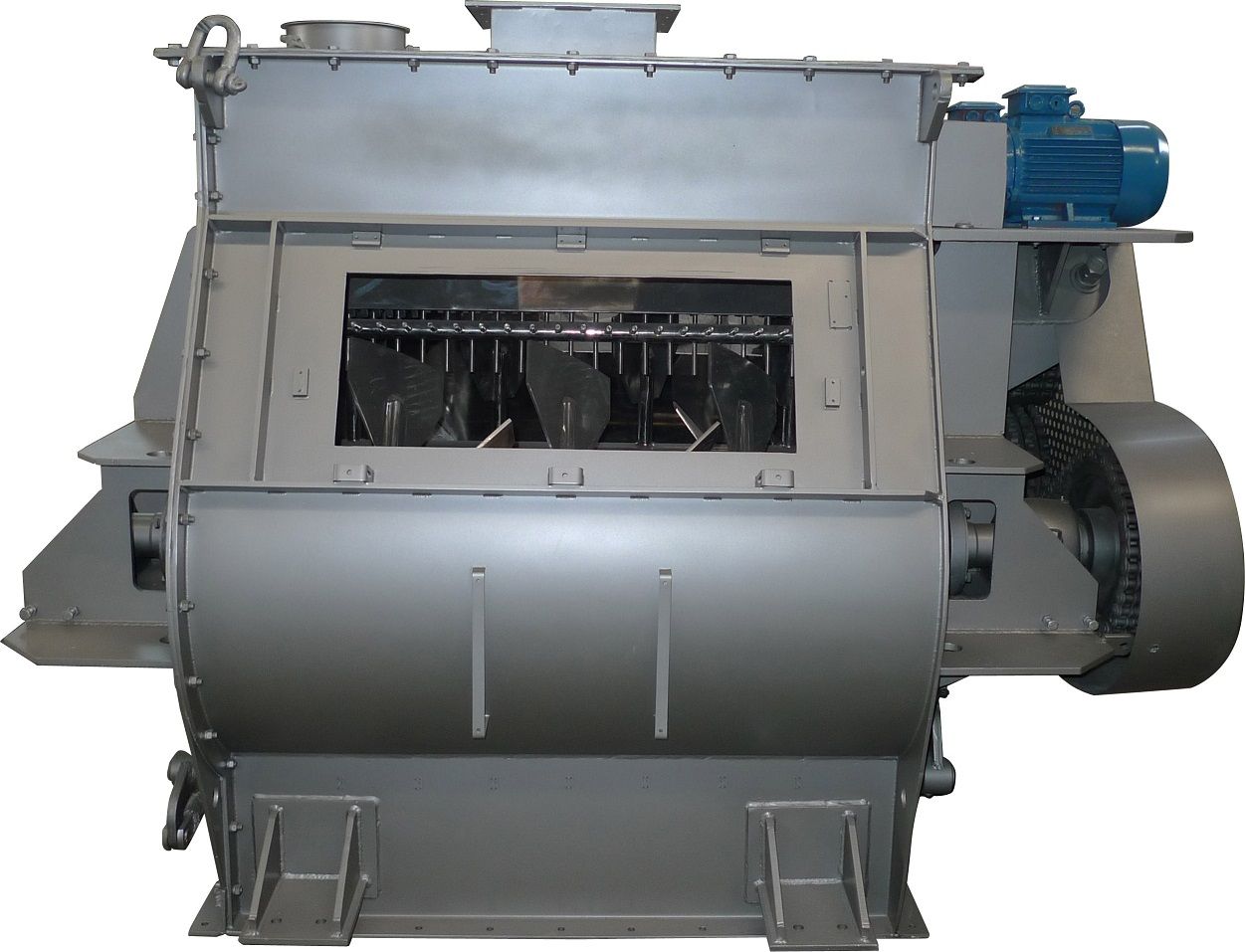

Continious Design Ploughshare Mixer

$5000.00 /piece

Product Details

Transaction Comments

Basic Info

- Model NO.: LDH0.1-20

- Working: Convection , Shear

- Certification: CE, ISO

- Layout Type: Horizontal

- Operating type: Continuous Operating

- Volume: 0.1-20

- Plough: Standard Plough or Toothed Plough

- Spraying Type: Atorizing Nozzle or Spraying Nozzle

- Trademark: S&L

- Origin: Shanghai, China

- Mixer Type: Horizontal Ploughshare Mixer

- Application: Liquid with Suspended Solids, Powder, Viscous Fluid, Granules

- Application Area: Ceramic,Alloy,Friction Material,Dry Mortar,Mine

- Mixing Drum Shape: Plough and Chopper

- Condition: New

- Feature: Continious Design

- Chopper: Multi-Bladed Chopper or Petalled Chopper

- Deliver Time: 40-60days

- Specification: CE, ISO9001

- HS Code: 84798200

Product Description

Introduction:

Plough Mixer is a high speed mixer with high homogeneity. During the mixing process, the raw materials are transferred around the drum in a radial, lateral and longitudinal movement by the high speed plough shears and choppers. Moreover, the mixing time is short, especially for free flowing powders or granules. Liquid additive and Heating or Cooling is also applicable.

Working Principle:

In the first case the mixing shaft and the tools are horizontally installed, thus achieving, at corresponding movement, a product reaching from a loose product bed up to a mechanically generated fluidised bed. In the second case the mixing shaft is installed in vertical direction, whereby a socalled vortex is built at corresponding movement. The installation of fast-rotating chopper heads enables the mixing of products tending to lump formation. Due to the mixing tools, the material to be mixed is hereby specifically fed to the activity area of the chopper head. Besides the conventional ploughshare mixing tools a large variety of modified mixing tools is available, facilitating an optimum adaptation of the mixing tools to the individual material.

Optional Features:

· Carbon Steel, Stainless Steel 304, Stainless Steel 316L

· Different type of plough according to material characteristics

· Internal pressure

· Sanitary type construction

· Flap valve, butterfly valve, slide gate valve, ball valve

· Horsepower to suit higher density materials

· Explosion-proof motors

· Controls such as variable frequency drives, motor starters and operator stations are available

· Spray nozzles for liquid introduction

· Jacket for heating or cooling

Datasheet:

Plough Mixer is a high speed mixer with high homogeneity. During the mixing process, the raw materials are transferred around the drum in a radial, lateral and longitudinal movement by the high speed plough shears and choppers. Moreover, the mixing time is short, especially for free flowing powders or granules. Liquid additive and Heating or Cooling is also applicable.

Working Principle:

In the first case the mixing shaft and the tools are horizontally installed, thus achieving, at corresponding movement, a product reaching from a loose product bed up to a mechanically generated fluidised bed. In the second case the mixing shaft is installed in vertical direction, whereby a socalled vortex is built at corresponding movement. The installation of fast-rotating chopper heads enables the mixing of products tending to lump formation. Due to the mixing tools, the material to be mixed is hereby specifically fed to the activity area of the chopper head. Besides the conventional ploughshare mixing tools a large variety of modified mixing tools is available, facilitating an optimum adaptation of the mixing tools to the individual material.

Optional Features:

· Carbon Steel, Stainless Steel 304, Stainless Steel 316L

· Different type of plough according to material characteristics

· Internal pressure

· Sanitary type construction

· Flap valve, butterfly valve, slide gate valve, ball valve

· Horsepower to suit higher density materials

· Explosion-proof motors

· Controls such as variable frequency drives, motor starters and operator stations are available

· Spray nozzles for liquid introduction

· Jacket for heating or cooling

Datasheet:

| Model Project | All volume (M3) |

Loads coefficient | Electrical machiney power (KW) |

Size(mm)× Max-diameter ×High | Equipment weight (kg) |

| LDH-0.1 | 0.1 | 0.4-0.6 | 3 | 1270×865×850 | 430 |

| LDH-0.3 | 0.3 | 0.4-0.6 | 4 | 2070×1050×1150 | 950 |

| LDH-0.5 | 0.5 | 0.4-0.6 | 5.5 | 2180×1200×1300 | 1100 |

| LDH-1 | 1 | 0.4-0.6 | 11 | 2830×1620×1550 | 1800 |

| LDH-2 | 2 | 0.4-0.6 | 18.5 | 3420×1810×1758 | 2520 |

| LDH-3 | 3 | 0.4-0.6 | 18.5 | 3420×2045×1983 | 3200 |

| LDH-4 | 4 | 0.4-0.6 | 22 | 4200×2140×2123 | 4836 |

| LDH-6 | 6 | 0.4-0.6 | 30 | 4680×2290×2448 | 8775 |

| LDH-8 | 8 | 0.4-0.6 | 45 | 5560×2390×2608 | 9360 |

| LDH-10 | 10 | 0.4-0.6 | 55 | 5140×2390×2850 | 9750 |

| LDH-12 | 12 | 0.4-0.6 | 55 | 5720×3110×2960 | 10660 |

| LDH-15 | 15 | 0.4-0.6 | 75 | 5920×3280×3140 | 11050 |

Other products from this supplier

Back to top