I am intrested in High Quality Hold-open Cast Iron Concealed and Exposed No Left and Right Installation Door Closer

Total procurement:500

2024-01-19 Expire Date

I am intrested in 16*25*40mm Carbon Brush for Locomotive Traction Motor Use

Total procurement:30

2023-12-28 Expire Date

Interested in wholesales self-locking plastic cable tie nylon cable tie style

Total procurement:

2023-08-31 Expire Date

I am intrested in COMPASAL brand china car tire 12 inch 145/70R12 145 70 12 145X70x12 for sale

Total procurement:10

2023-08-10 Expire Date 2023-09-30

I am intrested in Auto ac compressor For Thermo King Universal,OE TF22KL2E-42C-200,1020802

Total procurement:1

2023-06-23 Expire Date

I am intrested in New Arrive High Quality Metal Buckles Good Quality Waste Coat Buckles Metal Slider Buckles

Total procurement:2000

2023-01-02 Expire Date

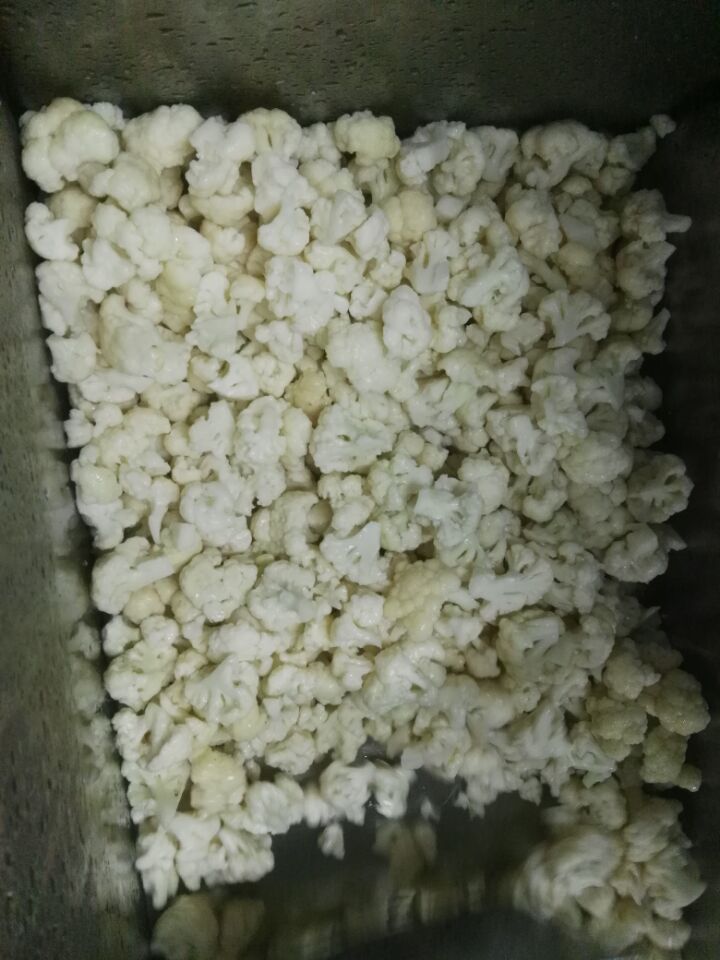

frozen garlic price in China

price: $1.00

frozen garlic price in China

price: $1.00

high-quality all-solid zirconia crowns and bridges, most suitable for Chinese dental laboratories

price: $15.00