Home

>Machinery & Industrial Parts » Machinery » Building Material Machinery » Window and Door Making Machine

HANGZHOU WILLING INTERNATIONAL CO., LTD

Business units

ChinaVIP0Audited Supplier

Products: Roll Forming Machine , Steel Coil and Steel Building Materials

Response Time: within 24 hours

Response Rate: 100%

+ Follow

View Shop

Chat Now

Add to wish list

+ Add a New List

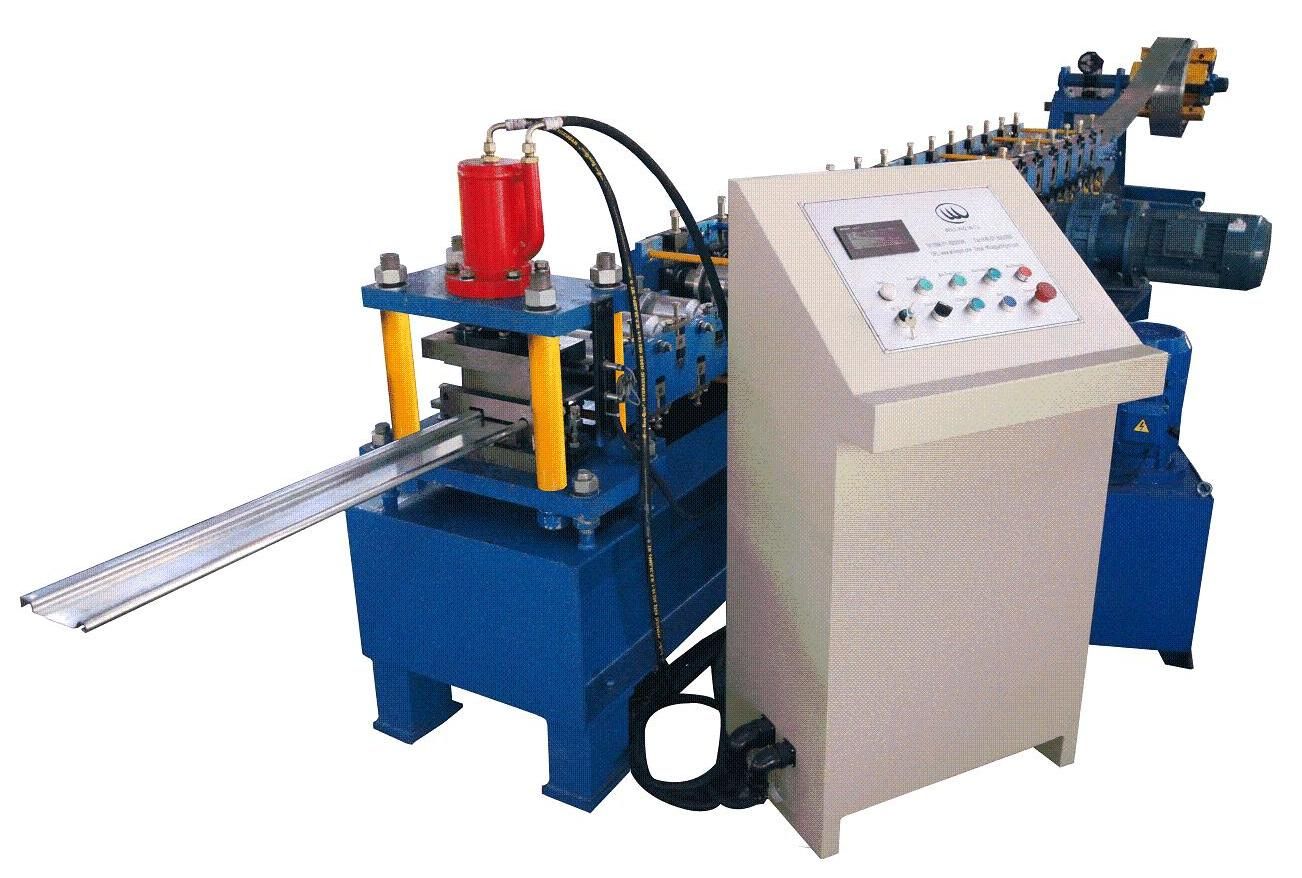

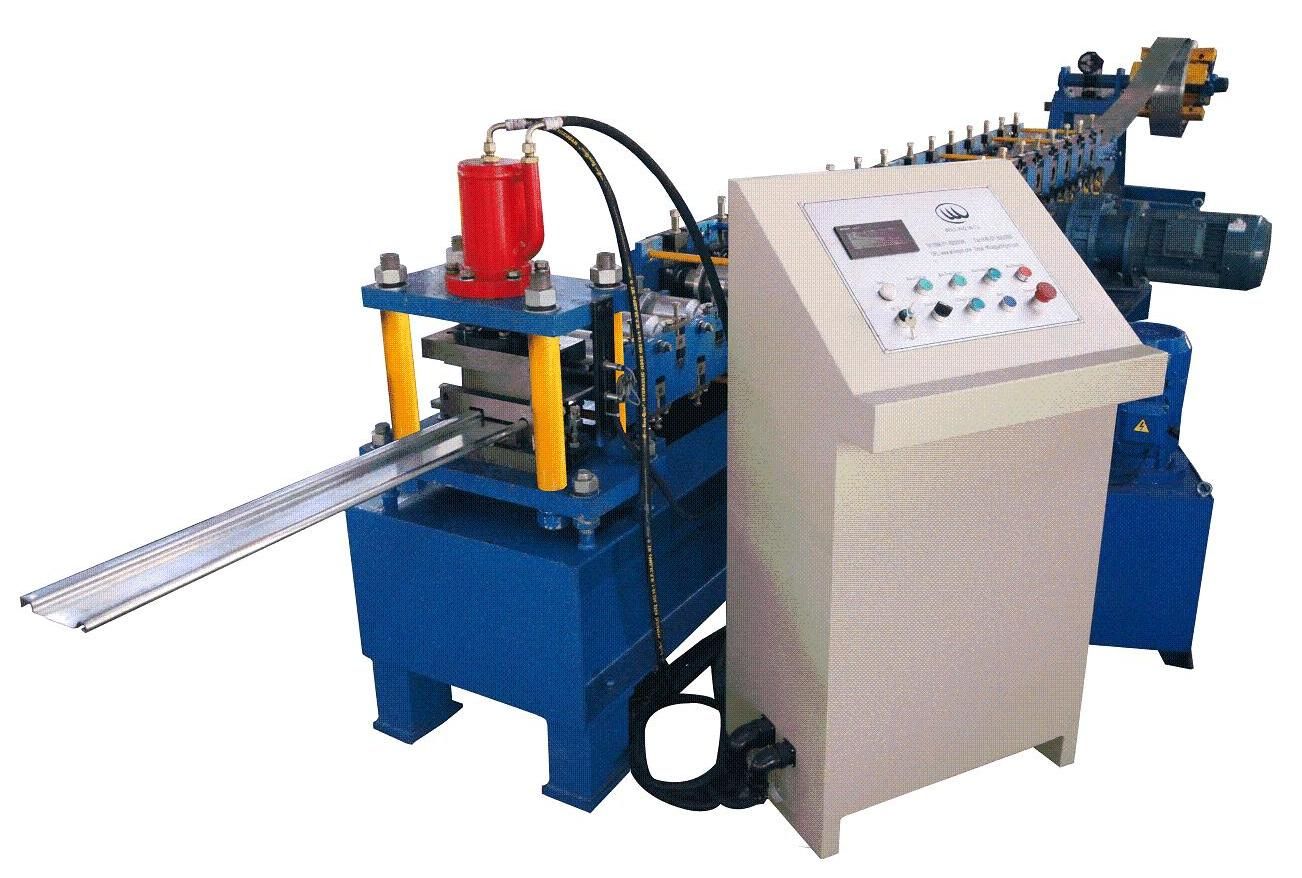

Shutter Door Rolling Forming Machine/Door Machine

$15000.00 /set

Product Details

Transaction Comments

Basic Info

- Model NO.: shutter door forming machine

- Certification: SGS, CE, ISO

- Customized: Customized

- Transmission Method: Electric

- Controlling System: PLC,Siemens

- Brand: Wling In′t

- Trademark: WLING IN′T

- Specification: 5000*1300*1300mm

- HS Code: 84552210

- Tile Type: Glazed Steel

- Condition: New

- Usage: Roof, Wall, Floor

- Type: Roller Shutter Galvanized Steel Door Frame Machine

- Guarantee Time: First Year Free, Lifetime Services

- After-Sales Service Provided: Engineers Available to Service Machinery Overseas

- Transport Package: Sea Worthy Fixed by Wire Rope, Woden Blocks

- Origin: Zhengjiang Hangzhou, China

Product Description

Subject: Rolling Shutter Door Roll Forming Machine

Components for the Machine

The roll forming machine consists of 3-ton manual uncoiler, infeed guide, fixed position driven forming stations, rectifying device, cutting equipment, hydraulic station, PLC control console, and manual unload product run out table.

Technical Parameters

Material of Main Equipment

Process Sketch:Uncoiling the sheet -Infeed guiding -Roll forming - Measure length - Rectifying - Cutting the panel - Panels to the supporter (option: automatic stacker).

Components for the Machine

The roll forming machine consists of 3-ton manual uncoiler, infeed guide, fixed position driven forming stations, rectifying device, cutting equipment, hydraulic station, PLC control console, and manual unload product run out table.

Technical Parameters

| Material Specification | aluzinc, galvanized and carbon steel. |

| Thickness | 0.8 mm to 1.2mm. |

| Main Motor Power | 5.5 kw. |

| Hydraulic Power | 3 kw. |

| Yield Stress | 235Mpa (33KSI) ~ 345Mpa (50KSI). |

| Roll Forming Speed | 12 m/minute. |

| Cutting Tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm |

| Manual Uncoiler | Max. Capacity: 3000kgs. |

| Coil Inner Diameter | 508mm. |

| Voltage | 380V, 3 phase, 50 HZ. |

| Numbers of Stations | 12 stations, and 2+3 rectifying rollers. |

| Type of Cutting | Roll-formed and length-set profile cutting. |

Material of Main Equipment

| Roller Material | High grade S45C forged steel, coated with hard chrome. |

| Active Shaft Material | High grade S45C carbon wrought steel, diameter 76mm. |

| Electric Elements | PLC control console, touch screen and transducer, from Siemens, Germany. Other elements, from Schneider Electric, Germany. |

| Cutter Blades | Cr12MoV steel with quenched treatment, hardness HRC58~61, wear-resistance, good steel structure, long life. |

Process Sketch:Uncoiling the sheet -Infeed guiding -Roll forming - Measure length - Rectifying - Cutting the panel - Panels to the supporter (option: automatic stacker).

Other products from this supplier

Back to top