Home

>Machinery & Industrial Parts » Machinery » Building Material Machinery » Window and Door Making Machine

WUXI LOTOS INTERNATIONAL TRADING CO., LTD.

Business units

ChinaVIP0Audited Supplier

Products: Door Shutter Machine , Roll Forming Machine , Bird Proflie Roll Forming Machine , Cut to Length Machine , Deck Floor Roll Forming Machine , Double Layer Roll Forming Machine , Glazed Tile Roll Forming Machine , Roof Panel Roll Forming Machine , Shape Roof

Response Time: within 24 hours

Response Rate: 100%

+ Follow

View Shop

Chat Now

Add to wish list

+ Add a New List

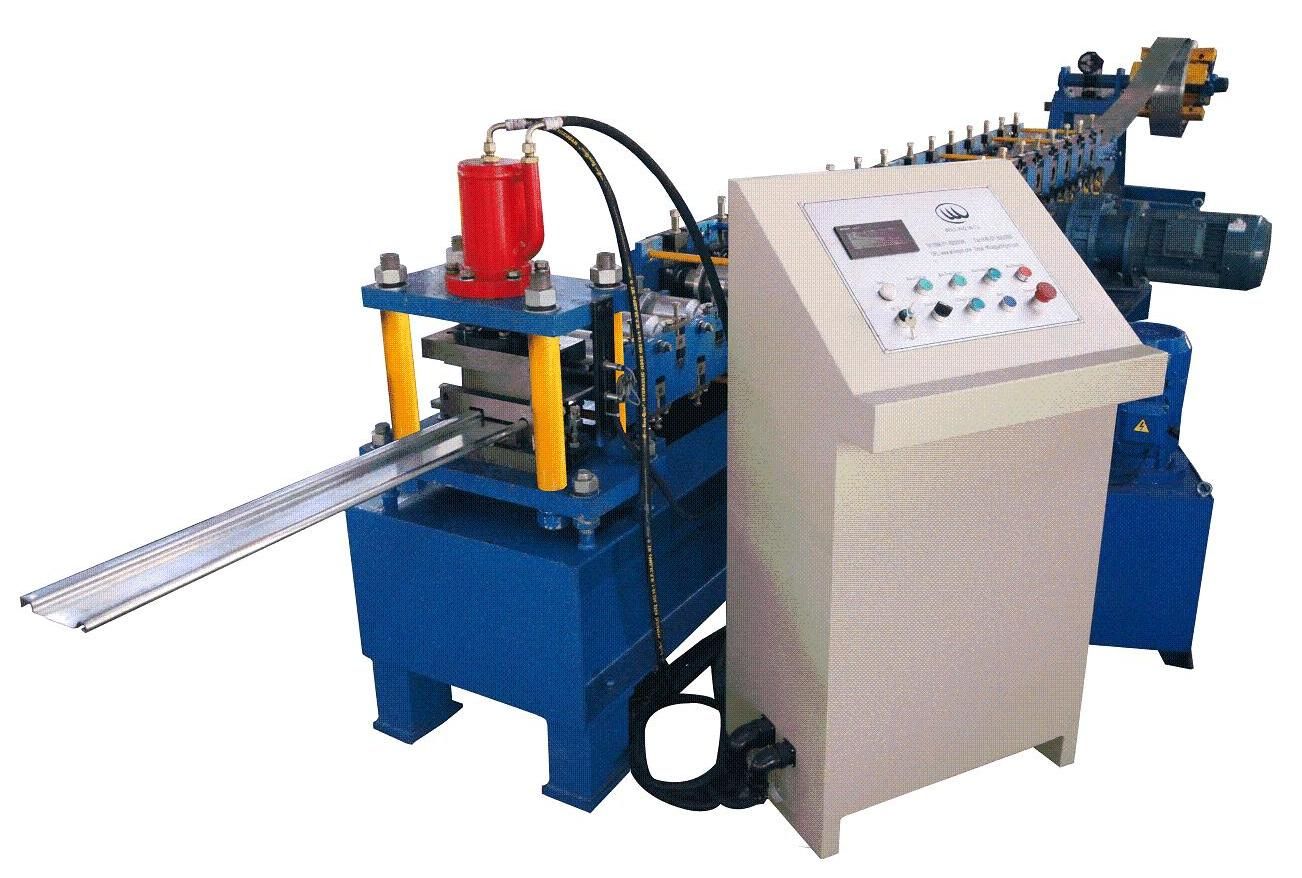

PU Foam Window & Door Shutter Roll Forming Machine 44mm

$18000.00 /piece

Product Details

Transaction Comments

Basic Info

- Condition: New

- Dimension: 36000*1600*1600mm

- Main Power: 11kw

- Tile Type: Glazed Steel

- Usage: Floor

- Trademark: LOTOS

- Specification: STEEL

- HS Code: 8455229090

- Certification: ISO, CE, SGS

- Material Thickness: 0.3-0.5mm

- Weight: 13 Ton

- Customized: Customized

- Transmission Method: Gear Box

- Transport Package: Container

- Origin: China

Product Description

Brief introduction:

The roll forming machines can produce various of steel roof and wall panel, it is a new building materials, the products are widely used as the roof and wall of factory, warehouse, garage, gymnasium, exhibition center, cinema, theatre, etc. It has many advantages, such as easy installation, short building period, beauty, light weight but high strength.

The roll forming machines can produce various of steel roof and wall panel, it is a new building materials, the products are widely used as the roof and wall of factory, warehouse, garage, gymnasium, exhibition center, cinema, theatre, etc. It has many advantages, such as easy installation, short building period, beauty, light weight but high strength.

| 1. Genaral | |

| Material: | Galvanized Coil, Aluminum |

| Material Thickness: | 0.3-0.5mm |

| Main roll forming machine Power: | 11 KW |

| Forming Speed: | 10-12m/min |

| Feeding width: | 229mm |

| Production line G/W: | 13T |

| Production line length: | about 38m |

| 2. Working Flowing | |

| |

| 3. Technical Parameter | |

| 3.1 Decoiler | |

| Decoiler Type | Manual |

| Loading capacity | 3Ton, Impassive to expanding |

| 3.2 Roll Forming system with feed panel unit | |

| Axis Diameter | 50 mm |

| Forming Roller station | 36+1 groups |

| Main Axis material | First grade 45# steel,heated and quenched |

| Roller material |

First grade 45# steel, Hard Chrome Coated, 2um heated and quenched |

| Pillar size | 42*45mm |

| Forming Speed | 10-12 m/min |

| Drive Type | Gear box |

| Machine Frame stand |

Welded structural steel, thickness 12mm |

| 3.3 Cutting Device | |

| Cutting type | Panasonic Servo tracking cutting |

| Cutting system power | 2.2KW |

| Cutting length tolerance | ±0.5mm |

| 3.4 PU Foaming Untit | |

| PU Raw material tanks |

A+B China good brand |

| 3.5 Electrical System | |

| PLC system | Japan PANASONIC/DELTA |

| Length Controller | Japan PANASONIC/DELTA |

| Operation | Touch Screen PANASONIC/DELTA |

| Inverter | Japan PANASONIC/DELTA |

| Voltage | 380V/50Hz/3P |

Other products from this supplier

Back to top