After cleaning the brush strip, the bristles need to be hung up and air dried with the bristles facing downwards.

3. After cleaning the brush strips, gently press with a tissue paper or cotton pad with your fingers to fully drain the moisture on the bristles. Remember not to twist the bristles, as this can damage the bristles of the brush strips and loosen the structure of the bristles, leading to hair loss.

4. The brush strips need to be air dried naturally and cannot be dried with a hair dryer, let alone dried in the sun, otherwise it may damage the material of the brush strips.

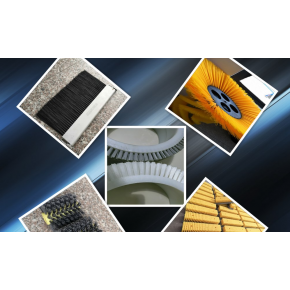

Let's briefly talk about the door and window strip brush. When passing through the rotating doors of the hotel, we often see a row of black bristles in contact with the door frame. That is the strip brush, which is set at the overlap between the doors to block dust. Therefore, when choosing, it is important to pay attention to comparison. Generally speaking, high-quality brushes are not only durable, but also can avoid temporary collisions between doors and walls, playing a buffering role, So as to prevent the wear and tear of sliding doors and extend their service life.

The following is a detailed description of how to clean the brush strip

1. Understand the cleaning methods for different materials

The materials used for brush strips can be divided into multiple categories such as synthetic fiber hair, animal hair, plant hair, etc. Each material has a different cleaning method. Therefore, before cleaning brush strips, it is necessary to first understand the type of material. For example, synthetic fibers can be affected by high temperatures and chemicals, making them prone to water absorption and swelling. Therefore, chemical agents can be chosen for cleaning. Animal hair and plant hair should not be washed with high temperatures or chemicals, and can be washed with water to clean the bristles.

2. Choose appropriate cleaning tools

The tools for cleaning brush strips usually include wire brushes, regular brushes, pressure water guns, cleaning machines, etc. Please choose a suitable cleaning tool for the material. When there is severe sediment, you can also use an ultrasonic cleaning machine according to the actual situation, and adjust the cleaning time and intensity according to the actual needs to achieve the cleaning effect.

3. Preprocessing

Before cleaning the brush strips, pre-treatment is required. Firstly, use a clean tissue or brush to remove dust and dirt from the surface of the brush strip. After checking that there is not much deposition on the surface of the brush strip, it is possible to partially soak the brush strip in cleaning solution to better soak and disperse the sediment during the cleaning process.

4. Clean the brush strip

Before cleaning, please ensure that you have selected the appropriate cleaning tool. When cleaning the brush strip, you need to pay attention to the following points during use:

(1) Before cleaning, the brush strip should be partially soaked in warm water or cleaning solution, and the soaking time should not exceed 30 minutes under normal circumstances.

(2) When using cleaning agents, attention should be paid to their concentration and usage methods to avoid damage to the brush strips.

(3) If using a high-pressure water gun to clean the brush strip, the water pressure and nozzle distance should be adjusted reasonably, and the nozzle should not be directly aligned with the brush strip to prevent the brush strip from being exposed and curled due to excessive water pressure.

5. Air dry brush strips

The cleaned brush strip should be immediately cleaned, wiped dry with a clean towel, and hung vertically in a ventilated area to dry, avoiding direct sunlight and preventing deformation and bacterial growth.

In summary, when cleaning brush strips, attention should be paid to using different cleaning methods for different materials, selecting appropriate tools and cleaning liquids, pre-treatment, and adjusting the cleaning method and time according to the actual situation, which will help maintain the cleanliness and service life of the brush strips.