Machine Function:

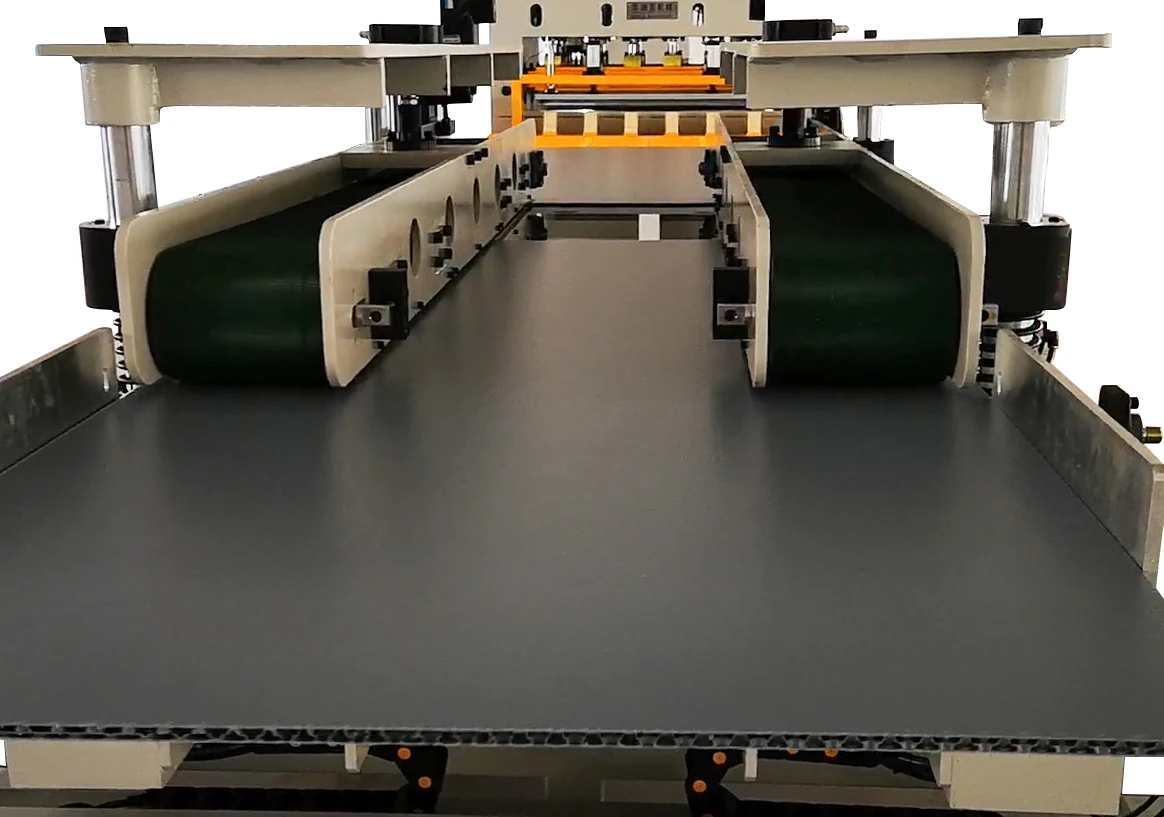

1: The machinehas the functions of cutting boards, sealing side materials on both sides, opening double windows, punching, six folding indentations, and finished product docking.

2: Automatic feeding function.(Optional)

3: The production speed can reach 2 minutes 30 seconds ~ 3 minutes per piece.

4: With the energy-saving function, each station has a material detection function, and the heating function can be turned off when there is no material.

5: Punching holes of different specifications can be achieved by replacing the mold, and selecting punching four holes or eight holes on the touch screen.

6: This production line is basically suitable for the size of the various specifications of boarding boxes on the market.

7: Applicable Steel Plates: Hollow plate, -shaped hollow plate, -shaped S-shaped hollow plate, and honeycomb plate.

For related equipment production video, please call us!

Configurations:

1. Pneumatic Component: Yadeke cylinder

2. Electronic Control PLC: OMRON

3. Operation Interface: Use 10.5-inch touch screen

4. Detection Sensor: Otis

5. Servo Motor: Yaskawa

5. Servo Motor: Yaskawa

7. Bearing: NSK